|

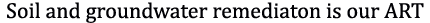

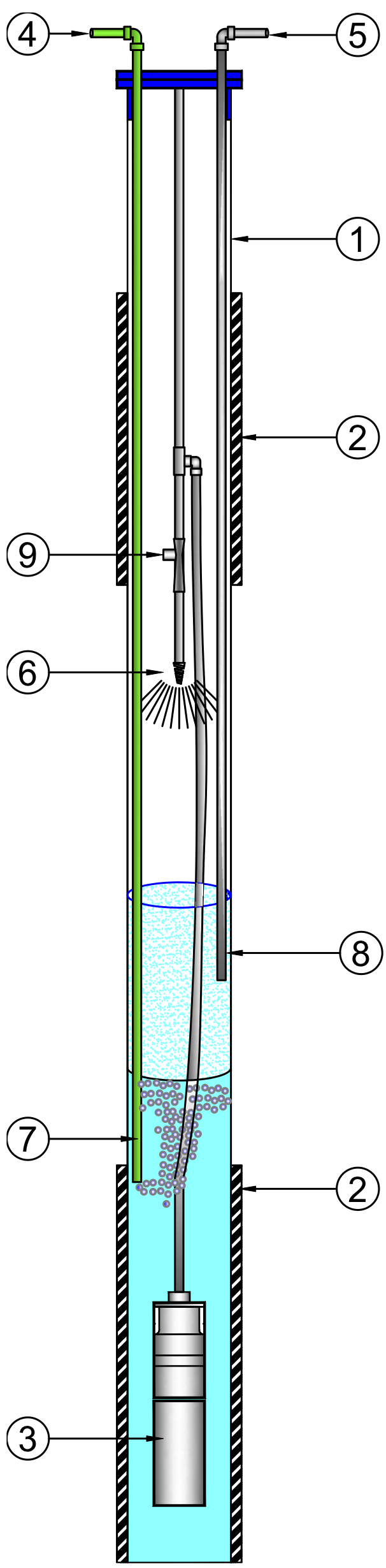

ART-PFAS technology has been developed and implemented as an in-situ remedy for the removal of PFAS and PFOA "forever chemicals" from the groundwater using simple yet effective processes. This remedial measure builds on the well- established and recognized circulating well concepts of the ART In-Well Technologies, with adaptations for the unique properties of PFAS and PFOA compounds. The ART- PFAS technology relies on maximizing the production of foam within the well followed by extraction and collection of foam via vacuum. The foam represents a liquid concentrate of the PFAS contamination from the formation and can then be transported for treatment on or off-site. Unlike other available PFAS remediation technologies, ART-PFAS eliminates the need to pump large quantities of sub-surface water for disposal or on-site treatment, which is extremely costly. Our technology enhances the capture of PFAS contamination from surrounding area to the ART well using the dynamic sub-surface circulation design.

|